Receive your tailor-made Astreïa quotation in your mailbox within 24 hours.

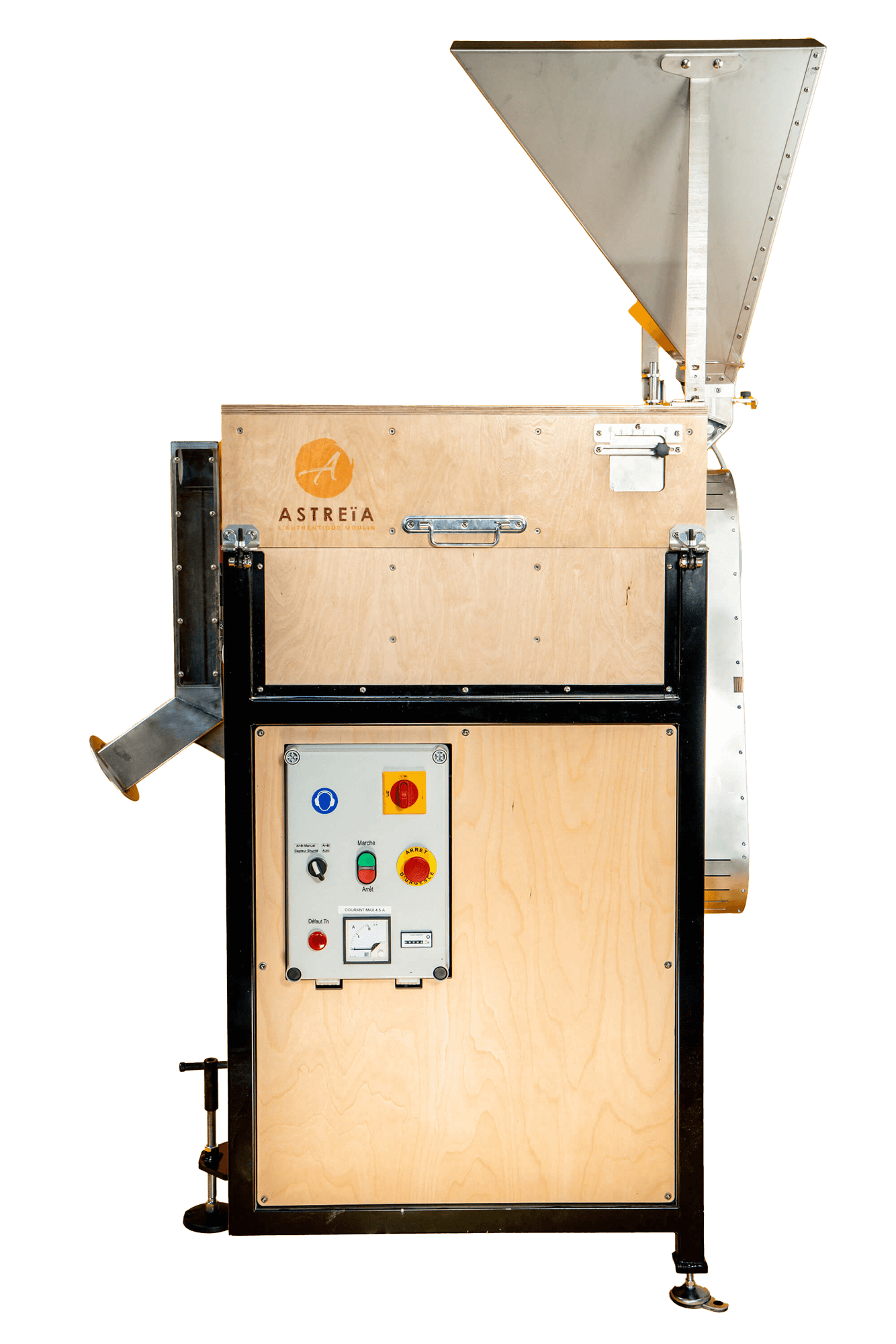

- Function(s) : Cleaning grains before grinding

- Brushes all types of grain with a smallest dimension greater than 1.5mm

- Hopper capacity: 55L, equivalent to 40kg of wheat

- Brush with nylon bristles

How the Astreïa grain brush works

The two nylon bristle brushes brush the grain against a cylindrical perforated plate made of high-strength steel.

The mechanical cleaning action is threefold:

- the bristles brush the grain

- the grain is rubbed against the perforated plate

- the grain rubs against each other

The grain is pushed through the cylinder by scrapers. As it exits, it passes through a densimetric column (optional); this is where the light fractions (straw, husks, leaves, etc.) that have not passed through the perforated plate are separated from the grain.

To best meet your needs,

options are available to complement our bean brush:

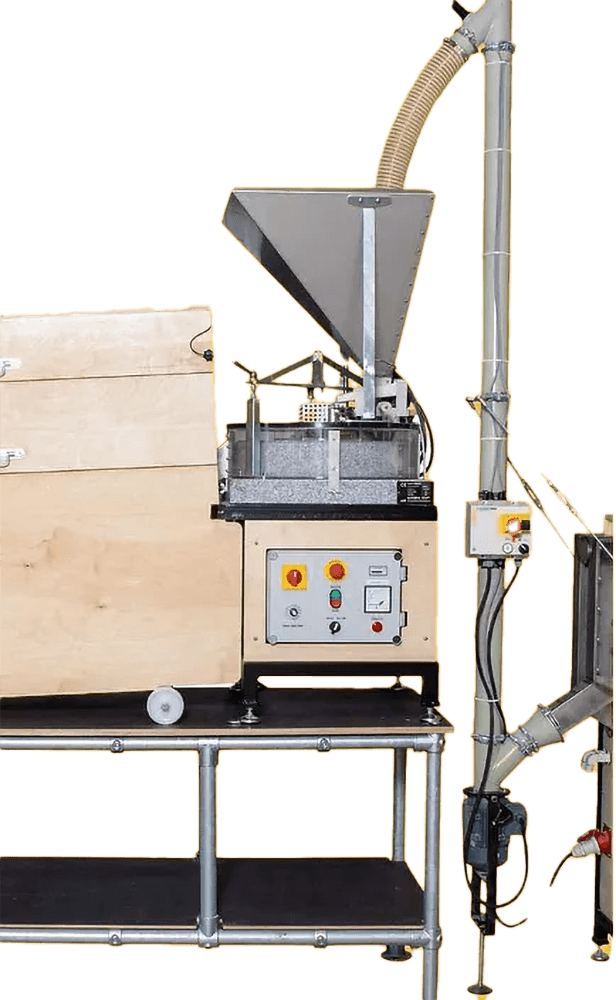

Autonomy pack

2 sensors to stop the brush if the hopper is empty or if the container at the brush outlet is full.

Timed capacitive sensor

Cables and plugs supplied

Densimetric column

Addition of a sorting function at the end of brushing to eliminate impurities that are too large to pass through the stator grid but lighter than seeds (husks, straw, chaff, etc.).

Cyclone and recovery bin to manage your waste

A cyclone separator mounted on a Big-Bag support separates the aspirated waste from the air stream; the waste (bales, straw, etc.) falls into the Big-Bag.

The cyclone is supplied with 2 watertight big bags of around 1m3, designed specifically for this type of application.

The air discharge connection to the outside of the building must be provided (Ø125mm pipe).

Cyclonic separator and BB support for husker and grain brush

For managing your waste

A cyclone separator mounted on a Big-Bag support separates the aspirated waste from the air stream; the waste (bales, straw, etc.) falls into the Big-Bag.

The cyclone is supplied with 2 watertight big bags of around 1m3, designed specifically for this type of application.

The air discharge connection to the outside of the building must be provided (Ø125mm pipe).

Gravity feed control kit for Grain Brush – Mill

This option enables the brush to be slaved to the mill in a configuration where the brushed grain flows by gravity into the mill (the brush is located above the mill, on the floor for example).

This ‘kit’ automatically fills the mill hopper (or other container) with freshly brushed grain when it is almost empty. This enables the Brush and Mill to operate independently and continuously.

Electrical adaptation – 220V power supply for the grain brush

This option offered by Astréïa allows you to ensure the continuous electrical operation of your mill to industrial standards and to provide after-sales service for your equipment.

Full technical specifications

Physical characteristics

Electrical power and energy

NB: Single-phase adaptation available on request

Throughput and yield

Removes up to 80% of dust and mycotoxins in a single pass, without damaging the grain.

From 200 to 700kg/h depending on the level of brushing required. The lower the throughput, the more intensively the grain is brushed.

Settings and maintenance

Automatic stop when the feed hopper is empty and when the downstream brushed grain container is full (capacitive sensors) – Optional with the autonomy pack.

Fine adjustment of brushing intensity via precise mechanical adjustment of incoming grain flow.

Adjustable, interchangeable brushes: the space between the stator grids and the brushes can be adjusted using the machine settings.

Easy brush adjustment and cleaning thanks to the hinged cover.

All our machines come with a 1-year parts and labour warranty, and for added peace of mind we offer preventive and corrective maintenance contracts.

Standards and installation conditions

Compliance with CE, food, safety and hygiene standards.

The machine must be anchored to the ground or to its platform for stability and safety reasons.

The machine must be placed close (<3 m) to an air outlet to the outside, in a closed room, protected from humidity RH%<70%, T°C between 10 and 40°C.

Find all the technical information in our free catalogue.

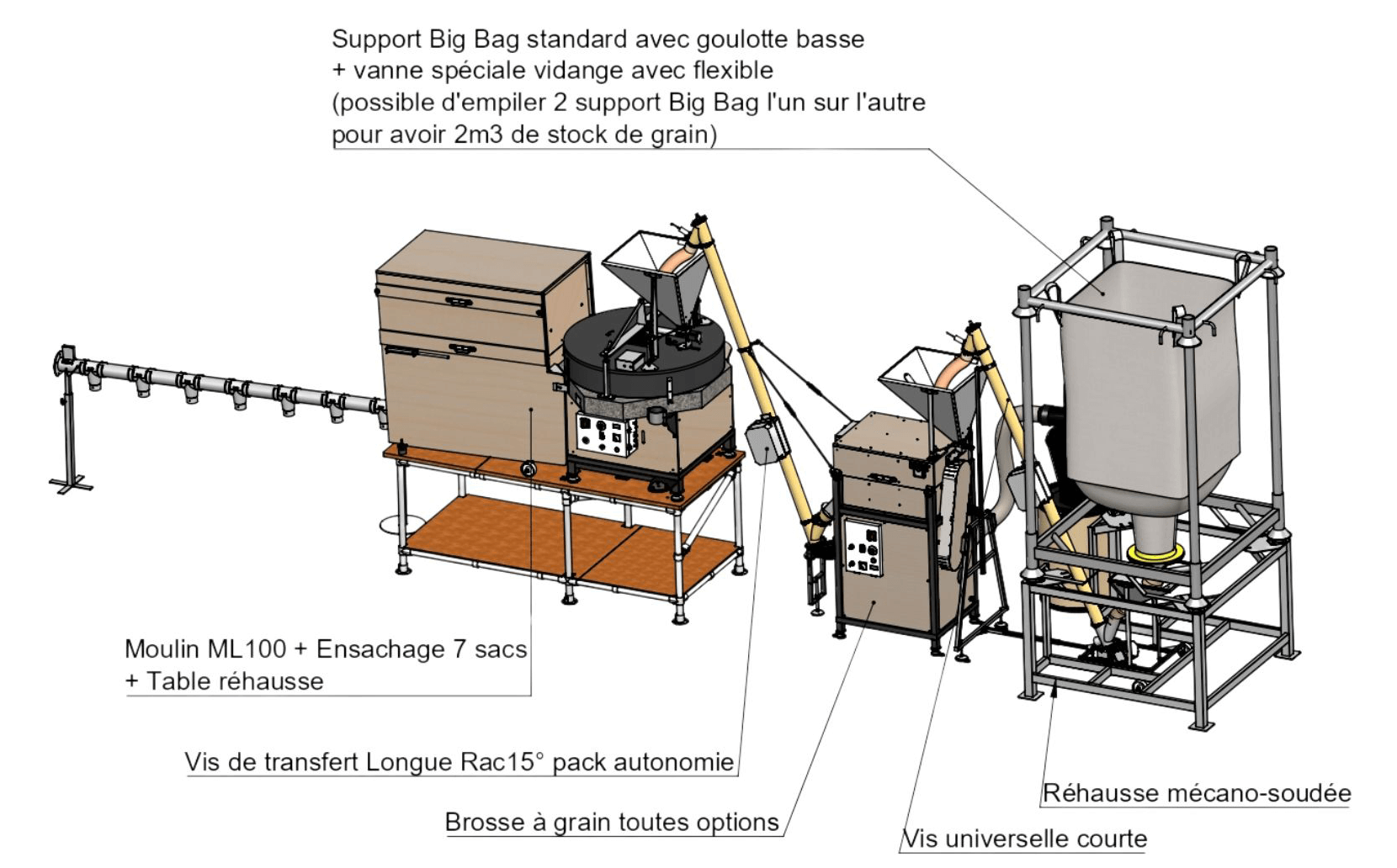

Gain autonomy

by integrating your Astreïa grain brush into a stand-alone installation